Cutter System Early Wear Detection

Improves Product Quality,

Reduces Expensive Scrap and

Avoids Production Loss

Shoreline AI delivers $2M in savings for Global Performance Material provider

Customer Background

Based in Houston, Texas, and with regional offices in Shanghai, Brussels and Detroit, the customer is a performance material solutions provider with global manufacturing facilities in North America, Europe and Asia. Their global workforce makes the materials used to make safer vehicles, cleaner energy, better medical devices, smarter appliances and longer-lasting apparel and consumer goods. They are committed to safety,

sustainability and the success of their customers and our communities.

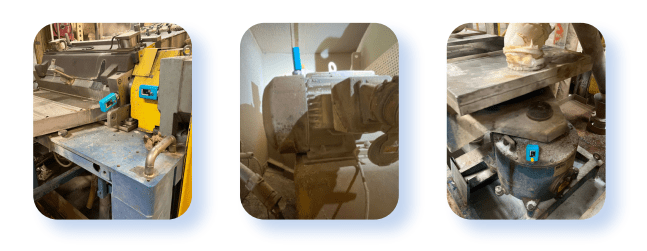

The company uses a variety of machines in the cutting production process, including electric motors, gearboxes, extruders, pumps, blowers, fans, conveyers, presses, balers, HPUs and chillers. They deployed Shoreline AI’s solution across a variety of assets to gain real-time visibility into machine performance and prevent downtime, scrap and reduced productivity.

Customer’s assets being monitored by Shoreline AI

Shoreline AI’s predictive maintenance analytics prevents cutter system failure

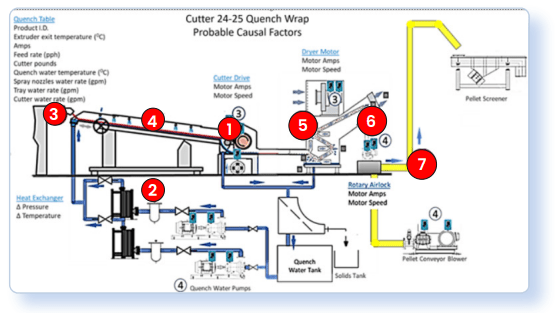

Shoreline AI’s custom cutter system AI model was deployed for real time monitoring of the entire power train’s behavior, including sensor and process data from several critical components of the cutter system:

- Feed roll to detect any blade problems

- Quench table water flow, temperature and pressure

- Material ID, viscosity and extruder exit temperature

- Water nozzle distribution, loss of pressure/flow

- Dryer system performance/plugging

- Rotary airlock performance and material flow

- Pellet conveyer blower to monitor for plugging

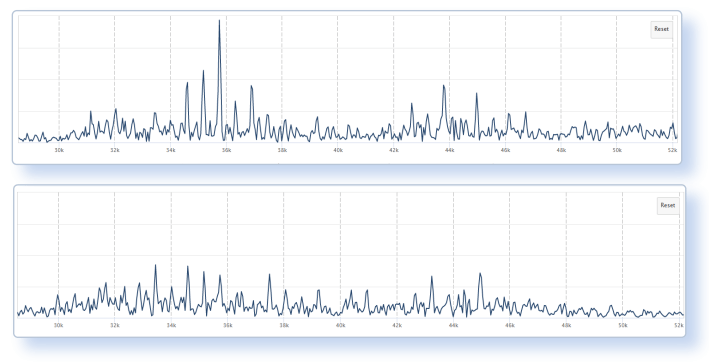

Normal vibration levels

Vibration-level anomalies

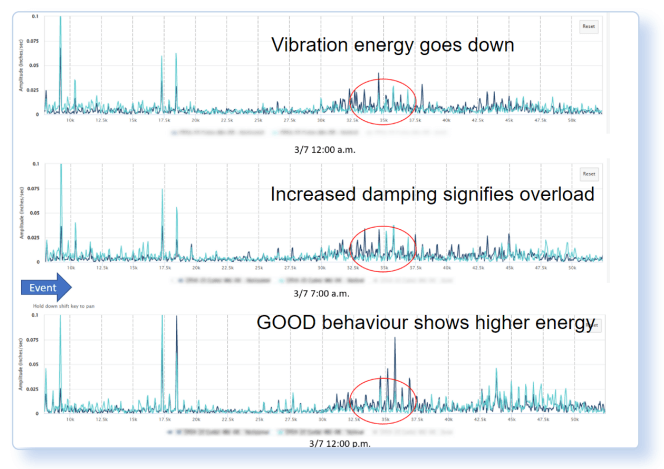

Increased loading on the motor dampens vibration levels, a few hours before wrapping

Results

As a result of implementing Shoreline AI’s solution, the customer estimated the substantial ROI from avoiding wraps, dryer blockages and conveyer jams at $250,000-$300,000 in a 3-month period. This estimate was based on just 2 events per cutter system per month, saving 10-20 hours of production downtime per year. This estimate did not include avoided repair costs. For a plant with 10 cutter systems producing Nylon-66 for example, this avoidance of up to 200 hours of downtime and lost production combined with lost material costs generated an estimated savings of $2.2M, not including maintenance costs.

About Shoreline AI

Shoreline AI’s plug-and-play asset performance management delivers breakthrough simplicity and cost efficiencies. Completely self-installed by non-experts, smart sensors automatically connect to the cloud and are auto-provisioned via a rich library of 30,000+ pre-built asset physics models.

This cloud-native approach requires no new CapEx, on-site experts or data scientists, operationalizing in days and delivering powerful machine-specific analytics. This highly secure, 100% subscription approach creates unprecedented industrial APM economics and scales easily for new applications such as emissions monitoring.

Shoreline AI helps clients in asset-intensive industries maximize the performance and profitability of their operations, create a proactive and predictive approach to asset management, and accelerate sustainability initiatives. The company’s solutions are designed for machinery serving the energy, manufacturing, pharma and data-center cooling industries.