Leveraging Gen AI for Industrial Asset

Performance Management

Introduction

In the near future, GenAI will further democratize APM, allowing anyone to execute complex queries and synthesis data in seconds. For example:

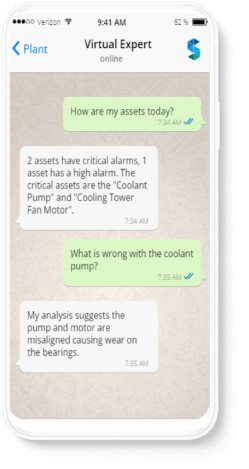

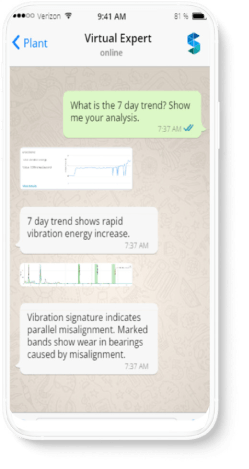

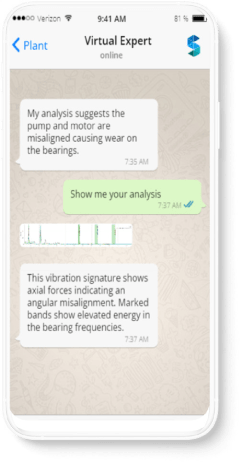

- Natural Language Interaction (NLI): A GenAI Virtual Assistant can be used to enable NLI in industrial APM software, allowing users to interact with the software using natural language commands and queries. This can make the software more intuitive and easier to use, especially for users who are not familiar with traditional data analysis tools. For example, users could ask the software questions about the performance of their assets, or they could instruct the software to perform specific tasks, such as generating reports or creating charts.

- Personalized UIs: The same Virtual Assistant can be used to create personalized UIs that are tailored to the specific needs and preferences of each user. This can be done by analyzing user data and preferences to identify common patterns and trends. For example, it can be used to automatically generate dashboards that display the most relevant information for each user, or to recommend specific actions that the user should take based on their current situation.

Beyond improving the simplicity of the user interface and quickly enabling every stakeholder to benefit from the entire teams’ knowledge capture, GenAI will combine human and machine data to improve nearly every aspect of asset performance management. This includes

- Anomaly Detection and Alerts: GenAI can be quickly detect anomalies in data and generate alerts to notify users of potential problems. This can help users to identify and address issues early on, before they escalate into major failures. For example, it could be used to detect anomalies in sensor data that could indicate an impending equipment failure, or to identify unusual patterns in asset performance that could suggest a problem with the asset’s configuration or maintenance schedule.

- Predictive Maintenance: GenAI can be used to predict the future performance of assets and identify potential problems before they occur. This can teams schedule maintenance proactively and avoid unplanned downtime. For example, it could be used to analyze historical data and identify patterns that could indicate an impending equipment failure. This information could then be used to schedule maintenance before the failure occurs, preventing unplanned downtime and costly repairs.

- Root-Cause Analysis: GenAI can also be used to identify the root causes of equipment failures by analyzing vast amounts of data and generating hypotheses. It can help users to address underlying issues and prevent similar failures from recurring. For example, it could be used to analyze data from multiple sources, such as sensor data, maintenance records, and operator logs, to identify the factors that contributed to an equipment failure. This information could then be used to implement corrective actions to prevent similar failures from occurring in the future.

Below are examples of a few tasks that can be quickly be answered by Shoreline AI’s Virtual Assistant:

- Show Assets that have exceeded “client defined thresholds” in the last 1 month e.g.

increasing Vibration-Trend AND/OR Temp-X AND/OR Speed-Y - Analyze performance of a particular make/model of a pump or compressor

operating across all client sites? - MTTR (Mean-Time-To-Repair) and MTTA (Mean-Time-To-Acknowledge) data to

understand if the responses are happening fast enough. Maintenance

Management information. - Which are the three most high-risk assets to review for asset health?

- What are key drivers for low asset health in region X?

- How many unplanned downtime events occurred in the last 30/60/90 days?

- What is the total duration of the unplanned downtime in last 30/60/90 days?

- Tell me the health diagnostics of asset [name].

- Highlight machines where vibration increases with speed on a graph/chart.

Representative/example queries

GenAI has the potential to make industrial APM software more user-friendly, effective, and valuable for users. By providing personalized UIs, enabling NLI, detecting anomalies and generating alerts, predicting maintenance needs, and performing root cause analysis, GenAI can help users to improve the performance of their assets, reduce downtime, and extend asset lifespan.

About Shoreline AI

Shoreline AI’s plug-and-play asset performance management delivers breakthrough simplicity and cost efficiencies. Completely self-installed by non-experts, smart sensors automatically connect to the cloud and are auto-provisioned via a rich library of 30,000+ pre-built asset physics models. This cloud-native approach requires no new CapEx, on-site experts or data scientists, operationalizing in days and delivering powerful machine-specific analytics. This highly secure, 100% subscription approach creates unprecedented APM economics and scales easily for new ESG applications such as leak detection, maximizing renewable assets, improving energy efficiency and emissions monitoring. Shoreline AI helps clients in asset-intensive industries maximize the performance and profitability of their operations, create a proactive and predictive approach to asset management, and accelerate sustainability initiatives. The company’s solutions are designed for machinery serving the energy, manufacturing, pharma and data-center cooling industries.