Challenge of a Net Zero Future

- The oil and gas, as well as chemical, industries are challenged to create sustainable solutions for a net zero future.

- Reducing methane and VOCs emissions across storage tanks, pressure relief valves and natural gas compressors is a key mitigation strategy to comply with current and emerging US and EU environmental protection requirements.

- Violations are expensive. Some states, such as California and Colorado, have already implemented fines of $15k to $25k per day for non-compliance. Other states are expected to pass similar laws soon.

- The EPA will implement a waste emission charge on methane emitted from applicable oil and gas facilities that emit over 25,000 metric tons of methane. These companies can be charged $900 per metric ton and the charge will increase in years after.

Problem to be solved

- Methane and other volatile gases escape from thief hatches, which allow hydrocarbon vapors to be emitted into the atmosphere. This is due to defective seals, open thief hatches or too much pressure in the tank.

- Fugitive emissions can go undetected and release methane into the atmosphere for an extended period of time, especially at remote storage tank sites that experience long periods between manual site visits.

- When a pressure surge in a compressor, pipeline, or pressure vessel exceeds the maximum operating pressure for the system, pressure safety valves (PSVs, or pressure relief valves, PRVs) will open and vent excess gas to the atmosphere. Over time, the valve seats wear or become fouled with debris, and will leak gas.

- Maintenance teams must know how long each thief hatch is open and confirm it’s closed and securely sealed to measure site emissions are in compliance.

Currently Available Solutions

- Data gets collected manually, but automation is now required for process efficiency.

- Early solutions had false signalling issues, as well as no distinction between a latched and unlatched thief hatch.

- Current solutions include expensive optical gas imaging (OGI) with an OGI camera costing between $150k to $500k.

- Fence line monitoring takes days to set-up and the leak location is not always precise.

Shoreline 24x7 Remote Emission Monitoring Solution

Highly Affordable & Scalable Solution available on subscription basis

- Uses smart sensors, edge & cloud-managed AI/ML analytics

- High accuracy with multivariate analysis

- Detects methane/VOCs emissions with real-time online alerts

- Set up in 10 mins – No wires, no routers/gateways, no power required

Smart & Reliable Remote Emission Monitoring Solution

Shoreline’s solution automatically monitors and detects methane and VOCs emissions – 24×7 in real time – to ensure environmental protection requirements are met.

The cloud connected sensors with edge analytics is easily set-up, requiring only 10 minutes per tank.

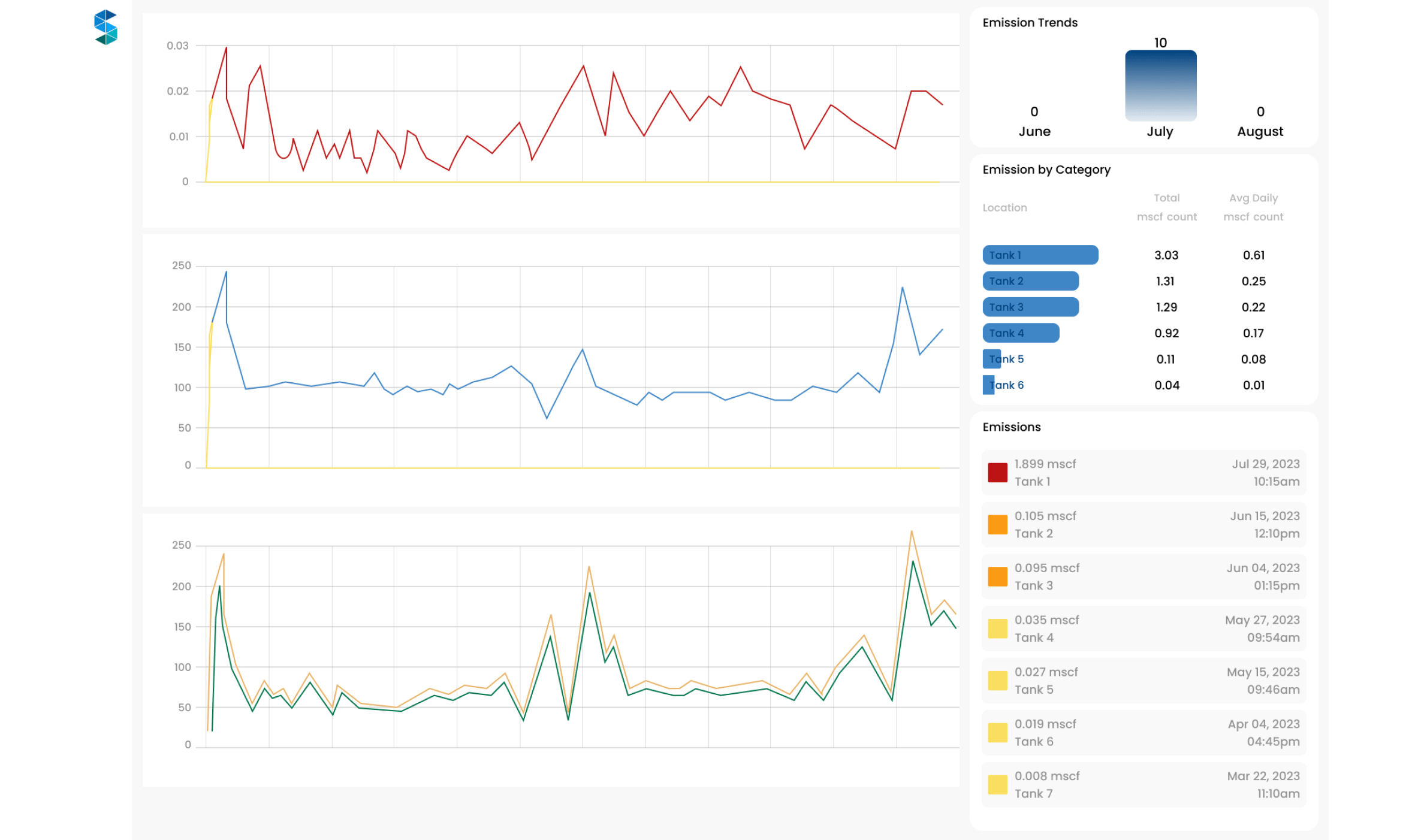

Precise location and timing of emissions is detected with proprietary anomaly models in the sensor and cloud

Shoreline's cloud-managed AI/ML analytics Platform sends instant phone alerts and notifications to field personnel.

Easy compliance reporting and logs including leak timing, duration, etc.

Benefits

Shoreline AI enables the Operations Team to detect and report methane/VOCs leakage and ensures they remain in regulatory compliance.

- Detect, document thief hatch emissions and be regulatory compliant

- Avoid costly super emission events and penalties

- Improve profitability due to reduction in loss of expensive hydrocarbons

- No upfront cost as it is available on subscription basis