Prime Conduit, a Mitsubishi Company,

Avoids Costly Extruder Downtime

with Shoreline AI

Shoreline AI Helps Global Conduit Manufacturer

Prevent Catastrophic Failure

Customer Background

Prime Conduit, a Mitsubishi company, manufactures superior conduit products for the electrical, telecommunications and utility markets. These products include Schedule 40 and 80 Electrical Conduit, P&C Duct, Split Duct, PV Mold, Telephone Duct and Conduit Elbows & Fittings.

The company uses a variety of machines in the production process, including electric motors, gearboxes, extruders, pumps, blowers, fans, conveyors, press, balers, HPUs, and chillers. They deployed Shoreline AI’s industrial asset performance management (APM) solution to gain real-time visibility, automate inspections, and enable early detection of asset maintenance.

AI functionality in asset performance strategy provides early warnings to minimize process interruptions, information to adjust the process, and ensures the right assets are available to match companies’ performance goals.

– Analyst, ARC Advisory

Customer’s assets being monitored by Shoreline AI

Shoreline AI’s predictive maintenance analytics

prevents extruder failure

One of the critical assets in the customer’s manufacturing process are extruders, which are used to melt and shape plastic, and other materials into various forms. Extruders are used to produce a wide range of conduit products for the electrical, telecommunications and utility markets.

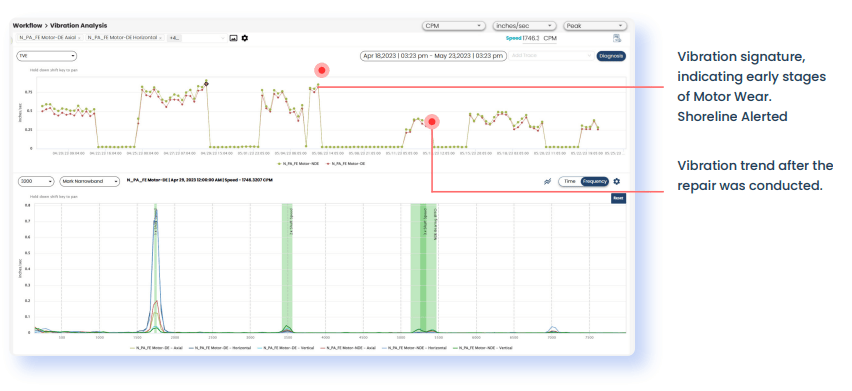

Shoreline AI’s predictive model compares detailed internal dynamics of the complete powertrain (e.g. motor, gearbox) to reveal specific frequency associated with key dynamics of the machine. Using narrowband and ML techniques, Shoreline’s solution automates reporting of anomalies and degradation, and provides detailed diagnosis and recommendation for maintenance and asset performance improvements.

Extruder failures cause significant disruption, and take hours to warm up, load, and begin production. Extruder downtime can cause significant bottlenecks and an entire shift’s shutdown, causing substantial production and machine losses estimated at almost $6,000 per hour. Extruder replacement or repair can take up to 3-4 months, resulting in more downtime and lost production.

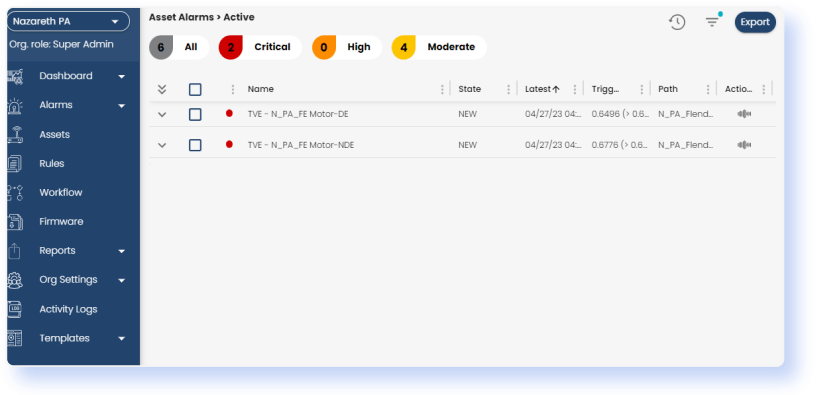

Shoreline AI's Intuitive Alarm Dashboard

with advanced insights

Detailed motor vibration data demonstrates a developing problem

Detailed motor vibration data demonstrates a developing problem

The Shoreline AI platform was able to alert the customer of an increase in the vibration trend as well as a precise analysis on where the anomaly was coming from. In this instance, it was the drive end of the motor.

Shoreline AI is extremely easy to use, and provides preventative AI-powered monitoring for changes in vibration, temperature and more, preventing major loss in production capacity. It gives us constant, real-time machine performance data to avoid catastrophic failure of gearboxes, screws, barrels and other equipment.

– Raymond Allen Grum, Plant Manager, Prime Conduit

Results

As a result of implementing the Shoreline AI solution, Prime Conduit is expected to eliminate unplanned downtime, reduce maintenance costs by 40%, and prevent millions of dollars in production losses. The expectation is this investment will also improve the quality of its products and increase customer satisfaction.

About Shoreline AI

Shoreline AI’s plug-and-play asset performance management delivers breakthrough simplicity and cost efficiencies. Completely self-installed by non-experts, smart sensors automatically connect to the cloud and are auto-provisioned via a rich library of 30,000+ pre-built asset physics models.

This cloud-native approach requires no new CapEx, on-site experts or data scientists, operationalizing in days and delivering powerful machine-specific analytics. This highly secure, 100% subscription approach creates unprecedented industrial APM economics and scales easily for new applications such as emissions monitoring.

Shoreline AI helps clients in asset-intensive industries maximize the performance and profitability of their operations, create a proactive and predictive approach to asset management, and accelerate sustainability initiatives. The company’s solutions are designed for machinery serving the energy, manufacturing, pharma and data-center cooling industries.