Natural Gas Compressor Predictive

Analytics Prevents Machine Failure

Shoreline AI helps global mid-stream Oil & Gas company

ensure optimal machine performance and remote

monitoring of its compression stations

Customer Background

This Fortune 500 natural gas company is dedicated to meeting the energy and consumer needs of our society. With a focus on technology and innovation, the company safely and reliably operates a strong and diversified portfolio of logistics, marketing, gathering, and processing industrial assets across nine states. They are one of the largest natural gas liquids producers and marketers, and one of the largest natural gas processors in the United States with over 90 years of industry leadership.

The company uses a variety of machines in the production process, including reciprocating compressors, engines, motors, bottles, tankers, pipeline, tanks and valves. They deployed Shoreline AI’s solution across 30+ locations and 110+ assets to gain real-time visibility, automate inspections, and enable early detection of asset anomalies including mechanical looseness, valve leakage and more.

Customer’s assets being monitored by Shoreline AI

Shoreline AI’s predictive maintenance analytics

prevents compressor failure

One of the critical assets in the customer’s manufacturing process are at compressors stations. To ensure the natural gas remains pressurized, compressor stations are equipped with machines needed to boost the pressure and maintain a constant flow through the natural gas pipeline system. These stations have compressors that use a turbine, motor, or engine to increase the pressure of the gas. These stations are located 40 to 70 miles along the natural gas pipeline to maintain the flow of the gas.

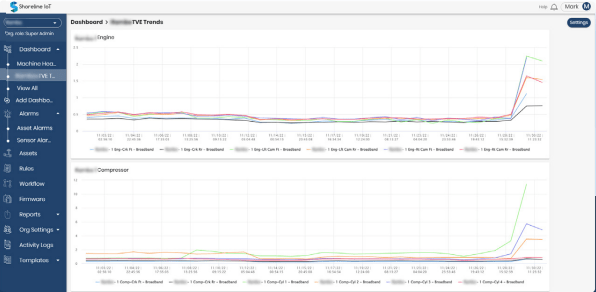

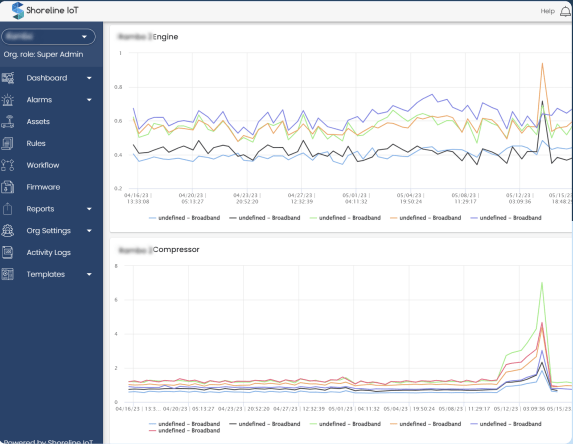

Shoreline AI’s predictive maintenances solution was deployed to automate detection of anomalies in the machines’ operating conditions. This includes mechanical and foundational looseness, liquid/gas entrainment, impeller vane erosion & lost capacity, conditions of bearings, power consumption & efficiency, valve malfunctions and emission detection.

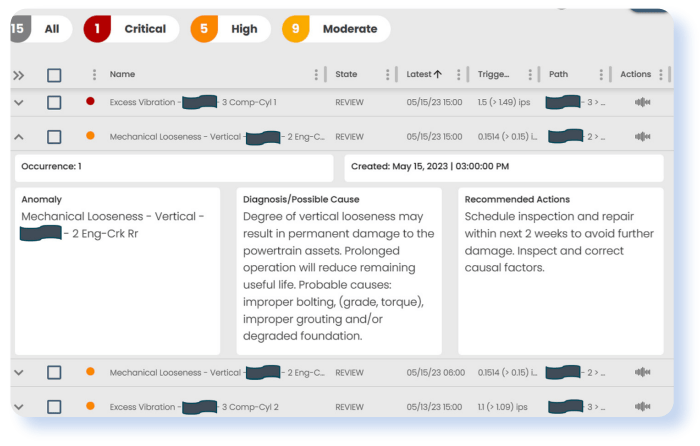

Recently, Shoreline AI’s software detected an abnormal vibration energy pattern, and generated a predictive maintenance alarm notifying the team of mechanical looseness in two of the compressors. They discovered a cylinder pedestal bolt had broken and loose pipe clamps on one compressor. On the other compressor they found loose bolts and missing shims on the cylinder supports and looseness between the distance piece and frame. Both situations posed the risk of catastrophic failure.

Thanks to early warnings of the anomalies sent to a smartphone via the Shoreline AI mobile app, the team was able to quickly diagnose the root cause and prevent machine failure. A failure of this type would have resulted in significant disruption, expensive repairs, productivity loss, and exceed $100,000 per incident. This does not include potential damage from leaks and possible fires and the resulting environmental impact.

Shoreline AI's Intuitive Alarm Dashboard with advanced insights

Early warnings of mechanical looseness led to corrective

action before catastrophic compressor failure.

Early warnings of mechanical looseness led to corrective action before catastrophic compressor failure.

Our company continues to explore and implement innovative technologies focused on operational excellence and digital transformation. Coupling Shoreline’s technology with our expertise in digitally enabling midstream operations, we see significant potential in this collaboration and are proud of the role we play in helping to bring new technologies focused on improving reliability & performance in the midstream industry.

– Group VP, Energy

Results

In Oil & Gas, the cost of an hour’s downtime has more than doubled in just two years to almost $500,000. With Shoreline AI’s solution, the customer is expected to eliminate unplanned downtime, and prevent millions of dollars in production losses. The expectation is this investment will also support future ESG requirements such as methane emissions monitoring.

About Shoreline AI

Shoreline AI’s plug-and-play industrial asset performance management delivers breakthrough simplicity and cost efficiencies. Completely self-installed by non-experts, smart sensors automatically connect to the cloud and are auto-provisioned via a rich library of 30,000+ pre-built asset physics models.

This cloud-native approach requires no new CapEx, on-site experts or data scientists, operationalizing in days and delivering powerful machine-specific analytics. This highly secure, 100% subscription approach creates unprecedented industrial APM economics and scales easily for new applications such as emissions monitoring.

Shoreline AI helps clients in asset-intensive industries maximize the performance and profitability of their operations, create a proactive and predictive approach to asset management, and accelerate sustainability initiatives. The company’s solutions are designed for machinery serving the energy, manufacturing, pharma and data-center cooling industries.