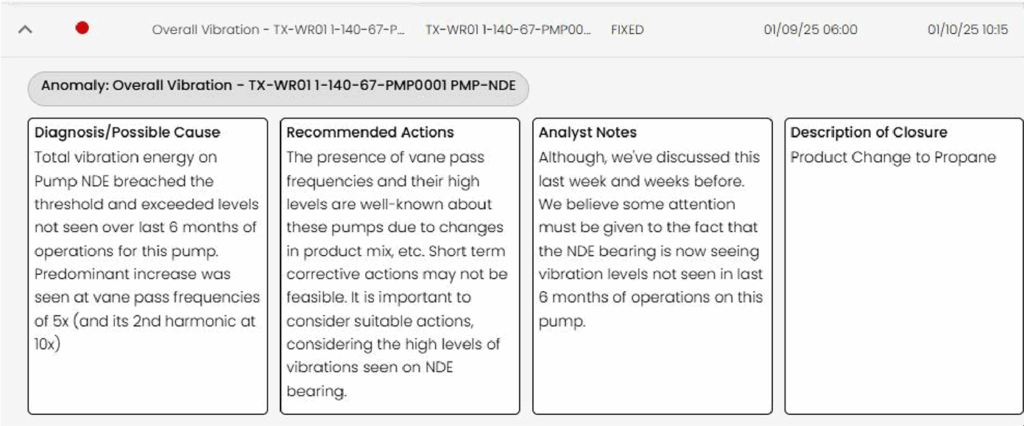

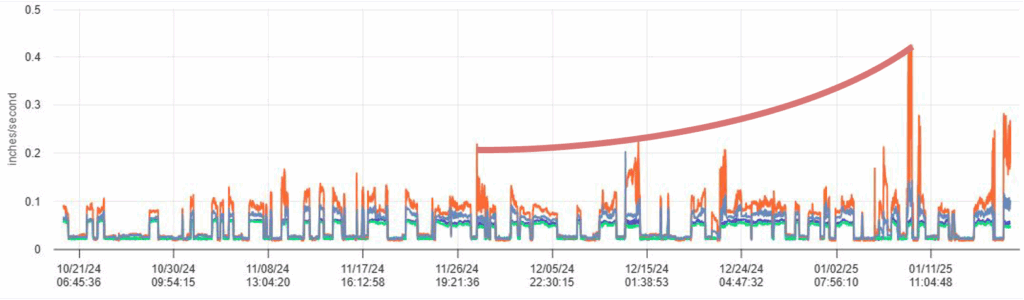

Shoreline’s plug-and-play asset performance management delivers breakthrough simplicity and cost efficiencies. Completely self-installed by non-experts, smart sensors automatically connect to the cloud and are auto-provisioned via a rich library of 30,000+ pre-built asset physics models.